Traditional Balsamic Vinegar: treasure of Emilia-Romagna

Traditional balsamic vinegar: a journey through the centuries

The history of the traditional balsamic vinegar of Modena is intertwined with the culture and traditions of Emilia-Romagna, dating back to 1046. Its evolutionary path led it to be appreciated as a precious gift among the nobility and, subsequently, to become a symbol of prestige and wealth also for the emerging bourgeoisie.

Origins and first references

Balsamic vinegar owes its first mentions to documents dating back more than a thousand years, where it was already recognized for its exceptional qualities. Over the centuries, it gained favor with the ducal courts, becoming a sign of distinction and a valuable item of trade.

Production and PDO specifications

the production process of traditional balsamic vinegar of Modena PDO stands out for its particular attention to the quality and origin of the ingredients. The grape must, the heart of the product, is transformed following traditional methods that ensure the maintenance of its unique characteristics.

The role of "batteries"

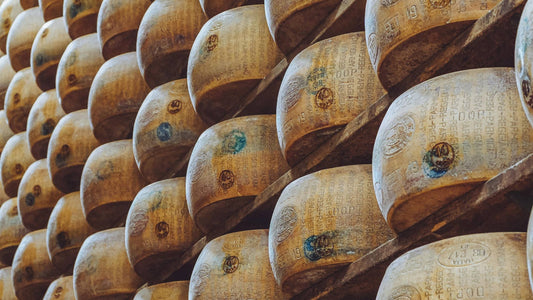

The "batteries" of barrels, essential for the aging of vinegar, represent a heritage passed down from generation to generation. these collections of barrels, often family heirlooms, are where balsamic vinegar matures and acquires its distinctive flavor.

Characteristics and tasting

With a dark brown color, a syrupy density and a perfect balance between sweet and sour, traditional balsamic vinegar of Modena DOP offers a unique sensorial experience. its aromatic notes and complexity make it ideal for enriching a wide range of dishes.

The tradition of balsamic vinegar tells of a passion for quality and an indissoluble bond with the territory of origin, demonstrating how a product can become an expression of the culture and history of a region.

The aging process of traditional balsamic vinegar

The aging process of traditional balsamic vinegar is critical to developing its rich, complex flavor. unlike the cellars, the barrels are kept in the attics, where the temperature variations between summer and winter favor bacterial activity and evaporation. In summer, the high temperature stimulates bacterial activity and evaporation, while in winter the process slows down, allowing the product to settle impurities.

Annually, a part of the contents of each barrel is transferred to the next smaller barrel in a precise sequence, thus concentrating the product until a very concentrated vinegar is obtained in the last barrel. The largest barrel, called "badessa", is the one into which the fermented cooked must is inserted every year, thus starting its acetification process.

The woods used

Production regulations require the use of specific fine woods for the barrels. among the most used we find oak and chestnut, which represent approximately 75% of the barrels. Other woods such as juniper, mulberry, cherry, ash and black locust are chosen based on the producer's preferences to give the balsamic unique colours, aromas and flavours.

Topping up and decanting

The production of balsamic vinegar is an annual process that involves taking the finished product from the smallest barrel and filling the barrels with the product from the immediately preceding barrel. This method of decanting and "topping up" with fresh cooked and fermented must is crucial to maintaining tradition and ensuring the quality of traditional balsamic vinegar.

The importance of family batteries in traditional balsamic vinegar

The family batteries, a series of barrels of different sizes and woods, are at the heart of the tradition of traditional balsamic vinegar. These batteries are not just aging tools but real treasures passed down from generation to generation, each with its own history, secrets and unique characteristics that influence the aromatic profile of the vinegar.

The passage of vinegar from one barrel to another, known as "racking", is a crucial moment that happens once a year, usually in spring. This process not only keeps the vinegar alive but also allows you to mix old vintages with new ones, creating a complexity of flavors and aromas that would be impossible to achieve otherwise.

The choice of woods

Each wood used in the barrels gives specific characteristics to the vinegar, from the oak which gives strength and structure, to the mulberry which adds sweetness, up to the juniper which embellishes the final product with resinous and spicy notes. The composition of the drums, therefore, is never random but the result of centuries of experience and experimentation.

A link between past and future

The maintenance of the family batteries represents a commitment towards the preservation of an unparalleled cultural and gastronomic heritage. Each barrel tells a story of dedication, care and respect for an art that defines the identity of Modena and its people.